Choosing the Right Color: Blue Tape vs. Green Tape in Powder Coating Tape

Choosing the Right Color: Blue Tape vs. Green Tape in Powder Coating Tape

Blog Article

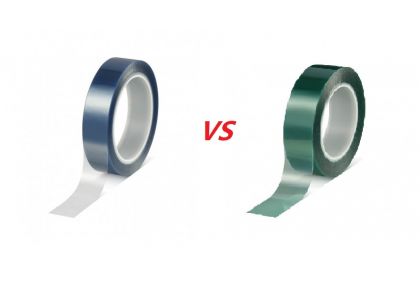

Choosing the right tape for powder coating projects is essential for achieving a clean and professional finish. Among the various options available, blue powder coating tape and green powder coating tape stand out as two of the most widely used varieties. While both serve the primary purpose of masking surfaces during the powder coating process, they have distinct characteristics that may make one more suitable than the other depending on specific requirements.

Understanding Powder Coating Tape

Powder coat masking tape is a specialized tape designed to protect areas that should remain uncoated during the powder coating process. This process involves applying a dry powder to surfaces, followed by heating to create a durable finish. Because of the high temperatures involved, the tape must be designed to withstand these conditions without peeling, lifting, or damaging the underlying surface.

Common Features of Blue and Green Powder Coating Tape

Both blue powder coating tape and green powder coating tape have several similarities:

High-Temperature Resistance: Both types of tape are crafted to endure the elevated temperatures that come with the curing process in powder coating. This ensures they maintain their integrity during high heat without losing adhesion.

Easy Application and Removal: Both tapes offer simple application processes, allowing for smooth handling. Additionally, they are designed to be easily removable without leaving sticky residue behind, which is crucial for maintaining a clean surface.

Versatility: Whether being used in automotive, industrial, or decorative applications, both tapes effectively mask surfaces on a variety of materials, making them versatile tools in the powder coating process.

Distinctions Between Blue and Green Powder Coating Tape

While blue tape and green tape share common features, they also have distinct differences that can affect their performance in specific applications.

Industry Standard: Green polyester tape is often regarded as the preferred industry standard for powder coating masking tape. Its proven reliability and performance make it the most economical and widely used option in the market. Many professionals trust green tape for its consistent quality and ability to perform under high temperatures.

Adhesive Strength: The adhesive properties can differ between the two tapes. Green powder coating tape typically features a stronger adhesive that can withstand more demanding applications, making it better suited for rough surfaces or projects requiring longer masking durations. This strength is particularly beneficial when working with materials that may experience movement or expansion during the curing process.

Thickness and Flexibility: Blue powder coating tape has a thinner carrier compared to green tape, which allows it to conform better to uneven or curved surfaces. This flexibility can be advantageous in applications where precise masking is required, such as intricate designs or detailed components. The thinner profile helps ensure a snug fit, reducing the risk of overspray getting under the tape.

Visibility: The color difference also plays a role in visibility during application. Blue tape is often favored for its bright color, which makes it easy to see against various surfaces. This visibility can help ensure complete coverage and identify areas that may need additional attention. In contrast, while green tape is also visible, it may not stand out as much on certain backgrounds.

Cost Considerations: While both tapes are effective, the cost may vary. Green powder coating tape is generally considered more economical due to its widespread use and availability. However, if a specific application requires the unique properties of blue tape, the investment may be justified.

Application Considerations

When deciding between blue tape and green tape, consider the specific requirements of your project. If visibility during application is a significant factor, the blue tape may be the preferred option. However, if the project involves rough surfaces or requires a stronger adhesive due to extended use, the green tape might be the better choice.

Additionally, think about the durability of the tape in relation to your specific application. For instance, if you are working with delicate surfaces or in an environment where the temperature fluctuates, ensuring you choose the right tape is crucial for achieving optimal results without damage.

Final Thoughts

Both blue powder coating tape and green powder coating tape serve important roles in the powder coating process. Their ability to provide high-temperature resistance, easy application, and versatility makes them essential tools in achieving a professional finish. Understanding the differences in adhesive strength, thickness, and visibility can help you make an informed choice based on your specific needs.

In summary, whether you opt for high temp powder coating tape in blue or green, ensuring that the selected tape aligns with the project requirements will lead to better results. When preparing for your next powder coating job, consider these factors carefully to maximize the quality and efficiency of your work.

#hightemppowdercoatingtape,

#greenpowdercoatingtape,

#bluepowdercoatingtape,

#powdercoatmaskingtape,

#powdercoatingtapesupplies, Report this page